Restek standards contamination

For the record, I think Restek is a good company. I have taken a tour of their facilities. It appears as if they want to do good and valid science. They are standards makers. In fact, they make ISO compliant standards. That is the top of the line.

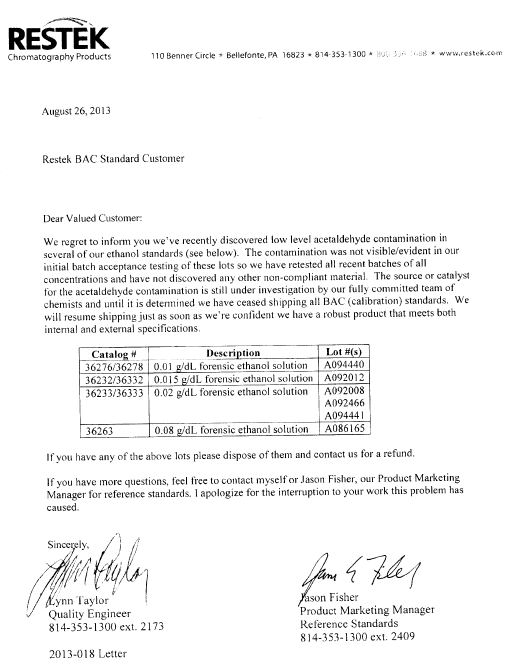

Here is a fine example of a good company that made a mistake. They disclosed the mistake too.

This is an important lesson to us all.

As Dr. Ludwig Huber, the modern day guru of method validation, GLP, GMP and other highly regulated analytical fields teaches us:

Testing for Performance Characteristics: Preparation and ExecutionGood preparation work is important for efficient experiment execution. Most important are the use of qualified material, qualified equipment,trained people and well documented procedures. Any chemicals used to determine critical validation parameters, such as reagents and reference standards, should be available in sufficient quantities, accurately identified, sufficiently stable and checked for exact composition and purity according to specifications.

It is the old metrology saying “You have to prove it before you can use it, and then prove it again.”

Even in the case of ISO Guide 30-35 Certified Reference Materials from a good manufacturer, we need to qualify the standards/controls that come into to the criminal laboratory. We cannot merely trust. We must verify. Every aspect must be put to the test and independently verified.

- Guess who labels these CRMs? A person.

- Who prepares these CRMs? A person.

- Who preforms that testing at the manufacturer? A person.

- Who prints and issues the Certificate of Authentication? A person.

Forensic Science is inhabited by people. People are as they always have been—subject to error. Here we have a case study of a very reputable manufacturer that is widely used that makes its standards in keeping with ISO standards with all sorts of testing and there still was failure.

[Hat tip to TCLDA and Deandra Grant for the information.]