Believe it or not, some testing labs who perform EtOH analysis still use direct liquid injection Gas Chromatography instead of headspace. When I say believe it or not, you will see by the end of this post that it is foolish to perform direct liquid injection especially looking for what is already a volatile organic compound (VOC) like EtOH.

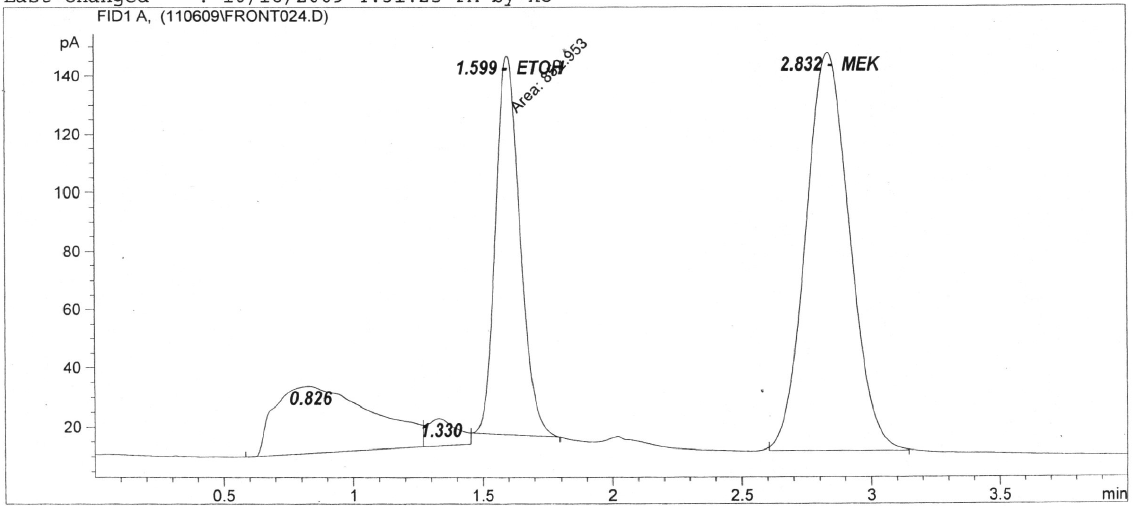

By looking at the chromatogram, how do you know if you have a case involving a direct liquid injection?

- A chromatogram evidencing Direct Liquid Injection

The hump-o-gram up front is best thought of like the solvent front. It is the “stuff” that they injected. Think of it kinda like in Size Exclusion-based Chromatography (SEC) with the un-retained analytes that do not interact with the stationary phase.

The injection volumes are 3 uL. That is way too small for headspace, and consistent with liquid injection.

So why is this a problem?

- There is a better way to do it. Use headspace when your target analyte is already a VOC. This will totally elevate the hump-o-gram up front as well as all of that ugly and sloppy integration computer work that we see around the baseline of the EtOH peak.

- In injecting water or blood directly, the water could have an odd cooling affect on the FID and the blood the same thing. That may be part of the cause of the “peaks” (humps) up front that we see.

- Whenever, we have direct liquid injection into the injector port we have to be very, very aware of the possibility of carry-over effect whereby the analytes of one sample are “carried-over” to another sample’s analysis. Think of it like contamination. The analytes from one sample stay on the column and then come out on the second sample. The old chromatographer’s adage and admonition in chromatography holds true. Just because you are done with the chromatography, it doesn’t mean the chromatography is done with your analysis. Analytical carry-over is a very real concern and phenomenon that happens even with headspace.

- This is why in the forensic arena we prefer headspace method of sample introduction as the sample is in a gaseous state when it hits the injector port and therefore is a lot “cleaner” and therefore the possibility of analytical carry-over is less (but not eliminated). When we do direct liquid injection, we MUST have blanks bracketing the unknowns (meaning both before the unknown and after the unknown) so as to demonstrate that there is no analytical carry-over.

Here is some information on carry-over in general:

The Carryover Effect: Lack of Blanks between tests leads to false positive or inflated BAC results

Carryover effect part Deux: Autodilution may be part of the problem for false blood results in DUI

Carryover effect part 3: Flushing of inert gas is not enough to prove there is no carryover

- In this case, that is a lot of matrix to inject directly. The major thing to worry about is the expansion coefficient of water or blood. Water expands about 1200 fold when it goes from a liquid to a gas (the next biggest thing is methanol with 500 fold, and most things are around 200). So 2 uL becomes 2400 uL (3 uL becomes 3600 uL) of water vapor. The largest injection port liners out there are only 900 uL!

The big concern is what we call liner overload. Anything over 900 uL tends to get lost out the septum purge. That leads to poor reproducibility. As most solvents in the world only expand 200-250 fold, very few people are aware of this huge problem with water. If they REALLY know what they are doing, they can use what is call a pulsed injection technique to remedy this. That means they have to significantly increase the pressure at the time of injection in order to squeeze the 2400 or 3600 uL down to 900 uL. VERY few people know about this technique. So either they are cutting edge, or are doing bad stuff. I’m leaning towards the latter.

- Agilent has a great (and free) solvent expansion calculator. You select your solvent from a drop down, along with the injector temperature and liner volume. It then calculates the expansion. You can then ratchet up the pressure in order to squeeze the volume into the liner. Here is the link:

http://www.chem.agilent.com/en-US/Support/Downloads/Utilities/Pages/GcPressureFlow.aspx

So, as we can see using direct liquid injection is really a formula for disaster. Just do it right folks.